Galvanised steel helps to protect structural steel against corrosion, allowing it to stay strong for many years, even over the course of decades with little maintenance required.

But galvanising has environmental advantages too, as the trade organisation the Galvanizers Association points out.

The organisation says: “Attention to durability of steel structures and components has important environmental, economic and social consequences. Some of these are less obvious than others.”

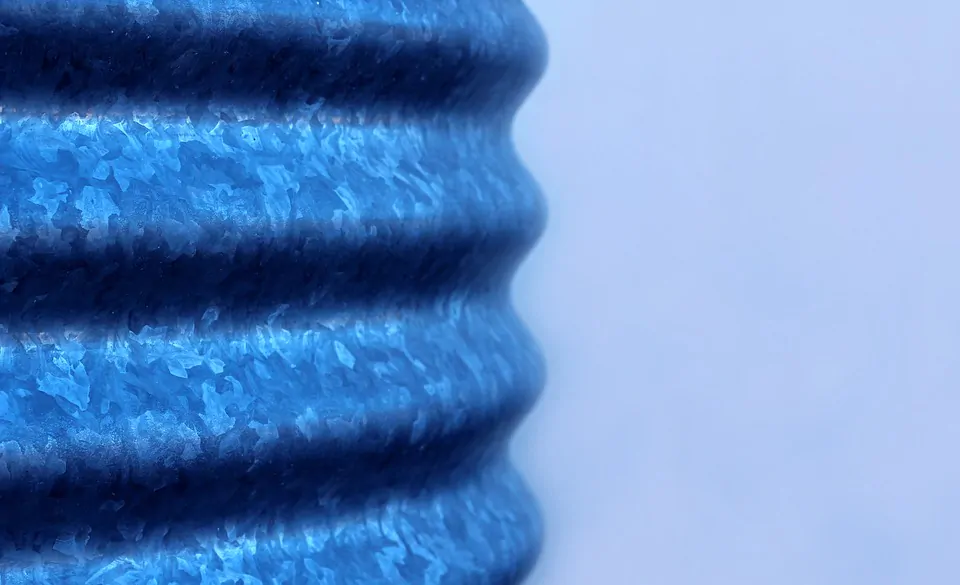

The impact of galvanised steel

For example, galvanising steel has a relatively small environmental footprint in terms of energy used and other factors.

This is especially true when considering the ‘energy value’ of the structural steel itself and the economic impact of corrosion – estimated at as much as 4% of GDP in countries where it has been studied.

Alternatives like paint can provide surface protection, but are less efficient than galvanising both in terms of the duration of protection they offer, and the environmental footprint of their use.

The Galvanizers Association adds: “Several studies have demonstrated the high economic and environmental costs associated with the repeated maintenance painting of steel structures.

“These burdens can be significantly reduced by an initial investment in long-term protection.”

Galvanising: A long term solution

The organisation warns about the “damaging economic legacy” of maintenance work that is required due to a failure to incorporate the best possible protection against corrosion when a structure is initially built.

For example in social housing projects, maintenance work to overcome problems like corrosion can add to the lifetime cost of owning and managing a residence for the relevant local authority or housing association.

And in large-scale public infrastructure projects, galvanised steel offers long-term protection, with less maintenance work required over the years and decades that follow.

This not only reduces the cost of maintaining a structure, but also means those public funds are retained and can be made available to other projects, allowing new infrastructure to be built that might otherwise not be possible.

Contact Dunkerley Steel for high quality galvanising

At James Dunkerley Steel we offer hot dip zinc galvanising, a cheap and effective way to protect exposed steel surfaces.

The steel can still be worked during assembly – the sacrificial zinc coating can continue to protect steel that has been cut or drilled, ensuring you continue to benefit from the economic and environmental advantages of this process.