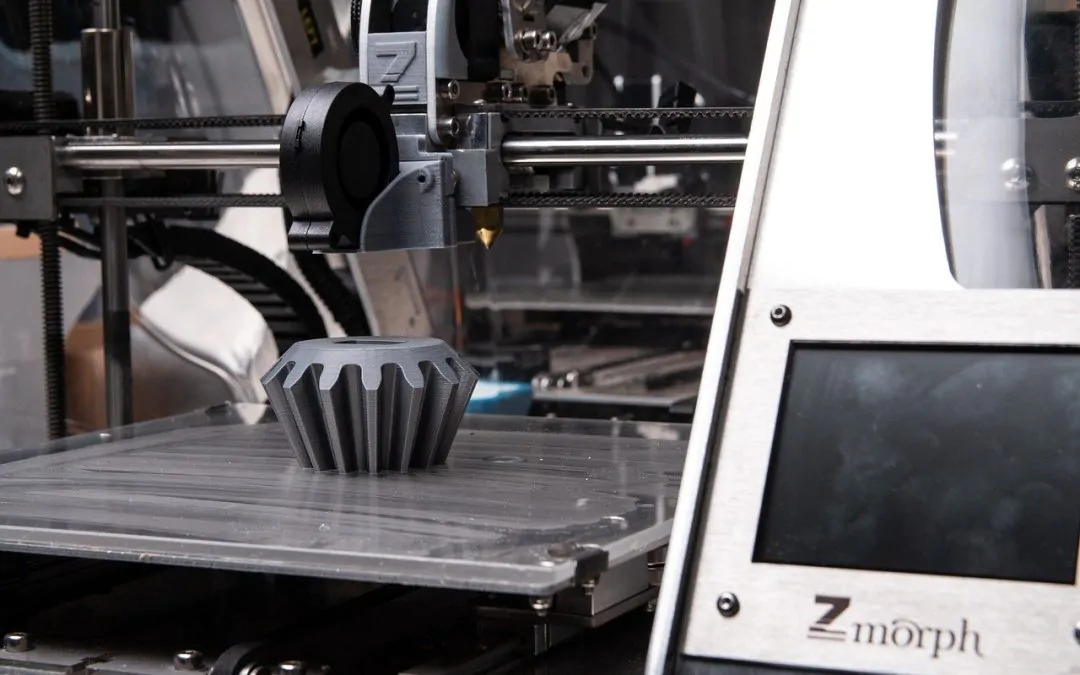

By now, most people have seen a 3D printer either in real life or online. Polymer 3D printers have become a frequent fixture in prototype manufacture and small parts production.

Simply design your item in a 3D CAD package, hit print, and watch as it appears replicator-style inside your 3D printer.

The process is highly flexible, allows a good amount of independence for individual designers and inventors, and can use recycled and recyclable raw materials – and all of this is true of steel 3D printing, as well as it is of 3D printing with plastic.

3D printing with metal is still less common, but starting to become an accepted technique, with some carmakers leading the march towards 3D printed steel parts in mass-market products.

So what is the current state of 3D printing in steel – how is it perceived and what can we expect in terms of widespread usage of 3D steel printers within the next few years?

Myths about metal 3D printing

There are already several myths about 3D printing, including:

Are 3D printed metals weaker?

Not necessarily. 3D printed metals can be as strong or even stronger than conventionally machined components, as the process creates a consistent material without seams or joins.

Do 3D printed metals warp?

Not if support structures are used. These attach the printed parts to the build platform and prevent distortion despite the high temperature of the process. They can easily be removed at the end.

Is unused metal powder wasted?

Not usually. Any unused powder can be collected and reused on the next build, so the total amount wasted is usually well below 5%.

Moving beyond the myths

As 3D printing in steel and other metals becomes more commonplace and affordable, there will be a natural increase in awareness and understanding of the process.

We have already seen this happen with polymer 3D printing, and a growing number of people now have a plastic 3D printer at home.

The future of 3D printing with steel is likely to follow a similar course, with a rise in small batch manufacturing and hobbyist use between now and the middle of the decade.

For more information on any of our steel products get in touch today.